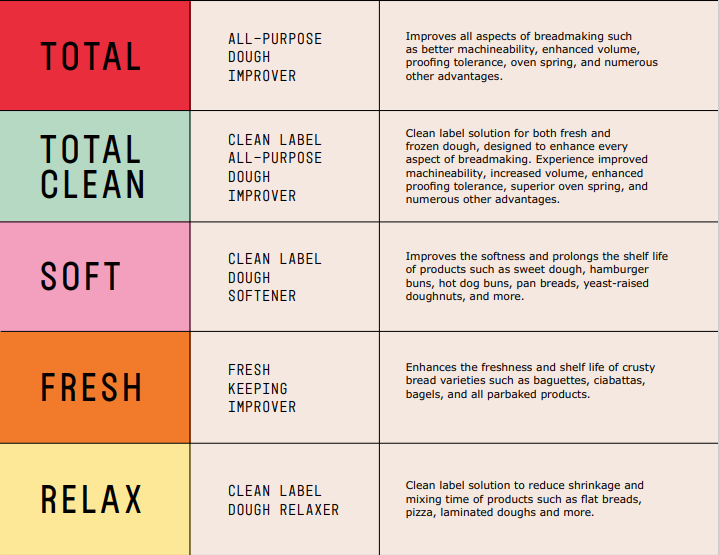

Discover the Lallemand Baking Solutions portfolio of enzyme-based conditioners here:

Enzyme-based products formulated without artificial additives or preservatives

Complete Dough Conditioners are crucial in modern baking, offering a solution to the myriad of variables affecting bread quality. By stabilizing the baking process, these products compensate for fluctuations in environmental conditions and ingredient quality, ensuring that each loaf meets the high standards expected by consumers.

Lallemand’s innovative blends effectively replace less label-friendly ingredients and fast-acting oxidizers, elevating their functionality while promoting a cleaner, more sustainable label. Discover their benefits and how these baking solutions can be your innovation.

Benefits of our enzyme-based complete conditioners:

-

- Created based on carefully selected enzymes. They are designed to be naturally tolerant and avoid overdosing.

-

- Designed for convenience, ease of use, and dosing, it replaces the functionality of less label-friendly ingredients and fast-acting oxidizers.

-

- Can be used to improve dough machinability, conditioning, strengthening, and stability.

-

- When used appropriately, they can also contribute significant time, energy, and water savings, extend shelf-life, and minimize waste management.

-

- Contain carefully selected and dosed functional ingredients blended, tested, and proven to provide you with consistent quality products.

In the dynamic world of bread production, the right improvers can make all the difference in meeting consumer demands for quality and consistency. Lallemand’s comprehensive range of improvers is designed for fresh, packaged, and frozen bread sectors.

Formulations are available for all types of dough systems and various baked goods applications, including breads, buns, rolls, pizzas, bagels, pretzels, tortillas, pies, pastries, and crackers.

Bread softeners that are more than just softness

Consumers want fresh, flavorful bread made with clean-label ingredients—not just at the moment of purchase but also during storage at home. Stale bread, buns, and cakes have a drier and crumblier crumb and are, therefore, less accepted by consumers. Stale bread is the cause of a significant amount of bread returns and waste.

Lallemand Baking can help bakeries overcome this challenge. Our enzyme-based softeners are designed to preserve crumb softness and moisture and extend shelf-life throughout storage time.

Benefits of Lallemand Baking softening solutions:

-

- Improve initial crumb softness (@ 3 days) and achieve better crumb softness (@ 28 days).

-

- Replace mono and diglycerides or distilled monoglycerides.

-

- Improve crumb resilience and springiness during the shelf-life period compared to monoglycerides.

-

- Delay moisture migration.

-

- Extends bread shelf life.

Lallemand’s softeners are suitable for a wide range of bread applications. Available for crumb softness as well as improved crumb texture.

Learn more on how to keep your bread fresher longer, reducing waste for a more sustainable food cycle.

Learn more by watching the video here.

Download the Application Guide here.

Achieve proper dough development with clean label enzyme-based dough strengtheners

Proper dough development is a critical step in the bread-making process. It ensures good machinability throughout production and achieves an optimal-proof height and oven spring. It can be achieved using clean-label dough development solutions such as dough strengtheners.

Proper dough development can be achieved using Lallemand’s enzyme-based strengtheners, which provide extra dough strength and replace traditional chemical dough strengtheners.

Benefits of Lallemand Baking dough strengthening solutions:

-

- Improve dough strength and stability, with possible cost savings by increasing gluten functionality and reducing added gluten by 20-50%, depending on the application.

-

- Reduce dough tearing, snap back & ovalization, minimize break & shred lines, and provide a more uniform crust color.

-

- Improve bread volume and give a more uniform final crumb.

-

- Replace chemical emulsifiers such as DATEM, SSL, and mono- and diglycerides and reducing agents such as L-cysteine hydrochloride.

Bake Time Reduction

Process optimization to reduce bake time - Save on energy and bake more sustainably.

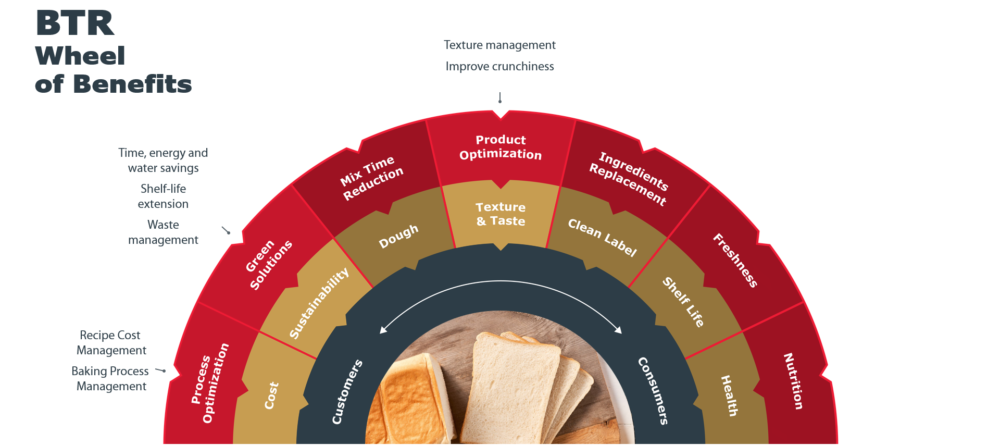

Lallemand Baking Solutions has developed the Baking Time Reduction (BTR) solution, addressing the critical need for energy conservation in the competitive baking industry.

The BTR solution is an enzymatic approach that modifies the water retention of dough, leading to shorter baking times by up to 33%. This not only enhances energy efficiency but also allows for increased production without compromising the quality of baked goods. BTR's clean label composition, utilizing proprietary enzymes, ensures the maintenance of product quality while supporting bakeries in achieving their sustainability objectives.

This innovative approach increases operational flexibility and presents various opportunities to enhance baking process energy efficiency. It enables bakeries to boost throughput, particularly in situations where oven capacity limits production. Furthermore, BTR facilitates energy conservation by enabling baking at lower oven temperatures, which is advantageous for bakeries with setups that cannot accommodate increased throughput.

Lallemand Baking offers a customized solution which can create a competitive advantage for bakeries while help them achieve a more cost effective and sustainable baking system. Using our tailored-made enzyme system designed for optimized formula and bake time reduction, bakeries will have the multiples benefits.

Learn more by watching the video here.

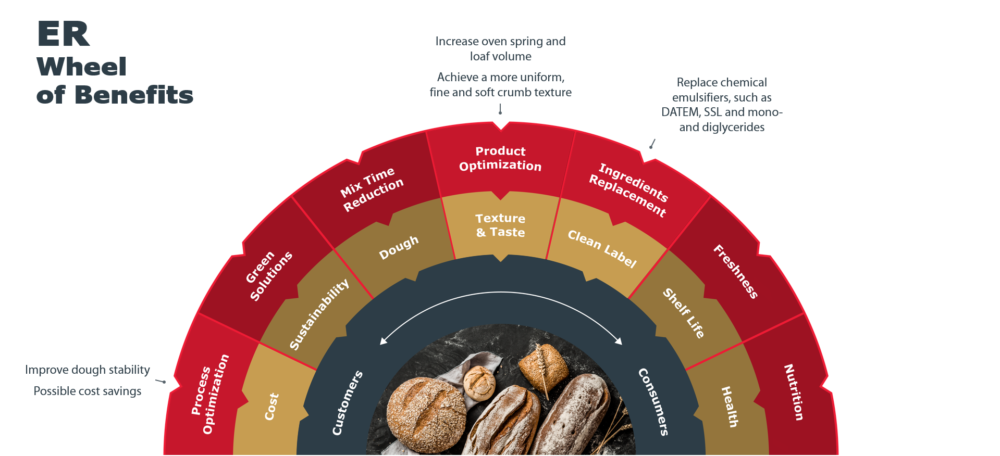

Emulsifier Replacement

Improve dough stability with clean label emulsifying solutions.

Chemical emulsifiers like DATEM, SSL, polysorbate, and monoglycerides are widely used in baking to enhance dough quality and bread characteristics, like they provide dough strength, improve dough extensibility, and loaf volume, and contribute to a softer and finer crumb structure. However, the trend towards cleaner labels and simpler ingredients is pushing bakeries to seek alternatives.

Lallemand Baking Solutions offers an Emulsifier Replacement solution, providing enzyme-based products that can replace these traditional chemical emulsifiers, aligning with consumer demand for more natural ingredients in their baked goods.

Download the Application Guide here.

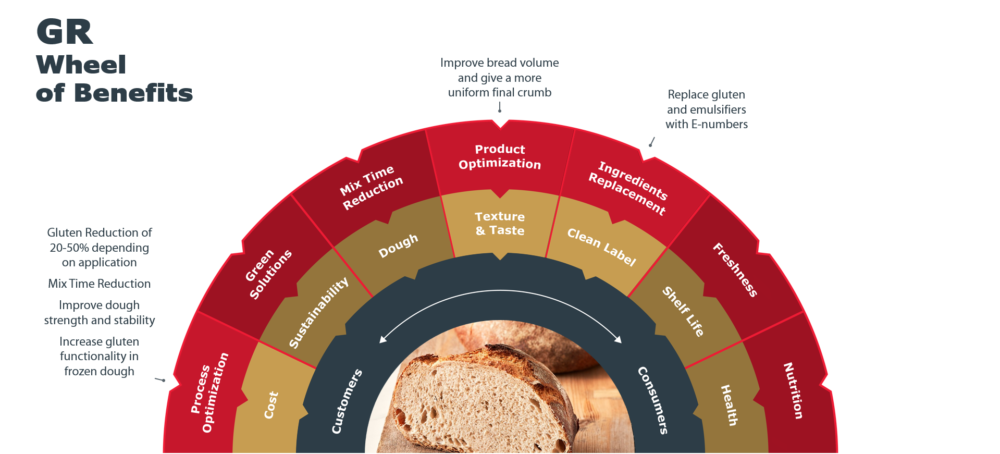

Gluten Replacement (GR)

Reduce the addition of vital wheat gluten and maintain good dough strength.

The protein content in wheat flour is not consistent annually, leading bakeries to add extra wheat gluten to maintain quality. Especially in multigrain and whole wheat breads, where abrasive components can damage the dough's protein structure, an increased amount of Vital wheat gluten is necessary. Typically, 1-2% of this gluten is added to enhance dough handling, but this can rise to 12% or more for breads with additional bran and fiber.

Lallemand Baking Solutions presents a competitive edge with its Essential® GR (Gluten Reduction) enzyme-based dough strengtheners. These products allow bakeries to produce high-quality bread while reducing the need for added gluten, leading to considerable savings on ingredient costs and enhancing the overall functionality of gluten in bread production.

Learn more on how to achieve reduce the added gluten and still produce high quality breads by downloading our Application Guide.

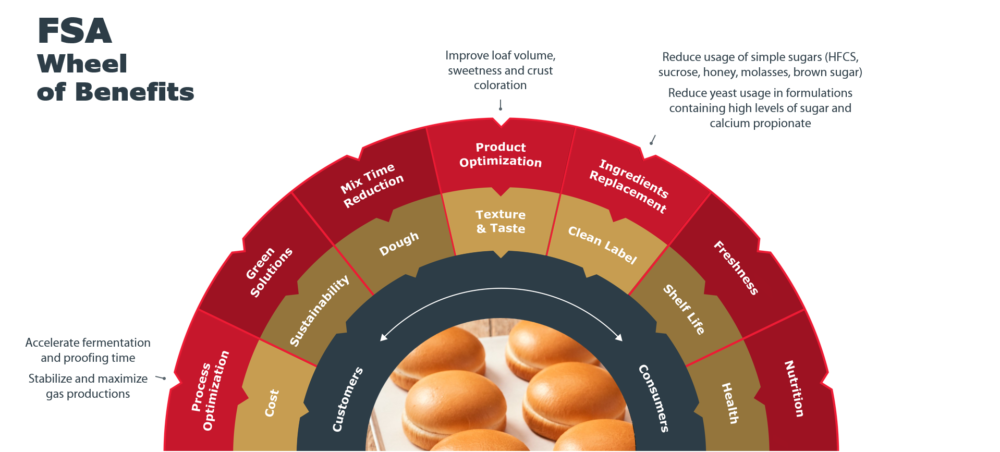

Sugar Management (FSA)

Reduce the amount of added sugar and improve yeast stability in low or no sugar formulations.

More and more consumers are looking for substituted sugar or unsweetened products. Unfortunately, sugar is not easy to replace as it plays many important functions in the bread making process. It serves as food for the yeast by providing a source of carbohydrates for yeast fermentation. It contributes sweetness to finished products and can also help mask the bitterness often associated to higher fiber products such as whole wheat and multigrain bread. Sugar also contributes to crust coloration and may increase shelf life.

Lallemand Baking Solution offers a solution which can create a competitive advantage for bakeries while help them better manage the sugar level in their formulations. Our Essential® FSA enzyme-based dough conditioner can be used to reduce the amount of added sugar and to improve yeast stability in low or no sugar formulations.

Learn more on how to optimize your production process and obtain quality Keto/Zero or Low Net Carb products by downloading our Application Guide.

Frozen Process (FTO)

Clean label solutions for frozen baked goods.

The rising popularity of frozen bakery goods is largely attributed to the cost-effectiveness and quality consistency afforded by centralized production and distribution. However, this trend also presents unique challenges for artisan bakeries, particularly due to the adverse effects of freezing on dough quality. Common issues include reduced volume and compromised texture, stemming from weakened dough and diminished yeast activity.

The freezing process can damage yeast cells, leading to decreased fermentation capability. This is caused by the expansion and crystallization of water inside the cells, which disrupts the cell walls. Additionally, the release of thiol peptide molecules during cell rupture can further impair dough structure and gas retention, resulting in excessive dough extensibility. Ice crystal formation also alters the dough's components, affecting the starch and gluten structures and ultimately reducing loaf volume.

Lallemand Baking Solutions offers clean-label enzyme-based baking solutions developed to improve moistness, freshness, cohesiveness of bakery products and prolong their fresh qualities throughout storage. Our enzyme-based dough conditioners for Freezer-To-Oven (FTO) can help to strengthen the dough and improve loaf volume.

Historically, Lallemand Baking has forged close partnerships with artisan bakers worldwide, crafting bespoke baking solutions tailored to their unique needs and commercial environments.

Building upon our century-old tradition of craftsmanship and ongoing collaboration with artisans, we proudly introduce LALTISAN, our new Premium Baking Solutions brand dedicated exclusively to serving the artisanal baking community.

Crafted by bakers for bakers, the Laltisan products are ideal for various bakery products.

Laltisan key advantages

- Simple Dosage

With a 1% dosage, you can’t go wrong. You are sure to get the perfect dosage every time. - 100+ Years in the Making

For over a century, we have been refining our products to ensure they stand at the pinnacle of artisanal baking solutions. - Local Products

LALTISAN products are meticulously

crafted by baking experts in state-of-the-art facilities situated in Montreal, Canada. - Team Spirit

LALTISAN’s dedicated baking experts serve as an extension of your team, ensuring superior results without compromising your craftsmanship.

You can find our enzyme-based conditioners & improvers under the following brands:

Essential® portfolio products are offered in all regions where Lallemand operates and are suitable for all types of bakery manufacturers.

Essential Tailored®, customized complete conditioners offered to industrial manufacturers in North America

LALTISAN is our line of baking solutions created for artisanal bakers in North America.

Not all products are available in all markets, nor all claims are allowed in all regions.