Bakeries face challenges when wheat flour’s protein content differs from harvest to harvest. Achieving consistent dough quality is essential for optimal processing. Problems such as overly elastic dough can lead to tearing during production, as well as issues with ovalization, shrinkage, and snapback, which can adversely affect the pan flow and the product’s final quality.

Reducing agents are key in achieving the desired dough relaxation and shortening mixing times. They also play a role in mitigating the impact of variations in flour quality. Enhanced dough relaxation helps avoid issues with overly tight or insufficiently mixed dough. While L-cysteine hydrochloride is a widely used reducing agent in bakeries, its common derivation from animal by-products like poultry feathers or hog hair necessitates the search for clean-label alternatives that align with consumer preferences.

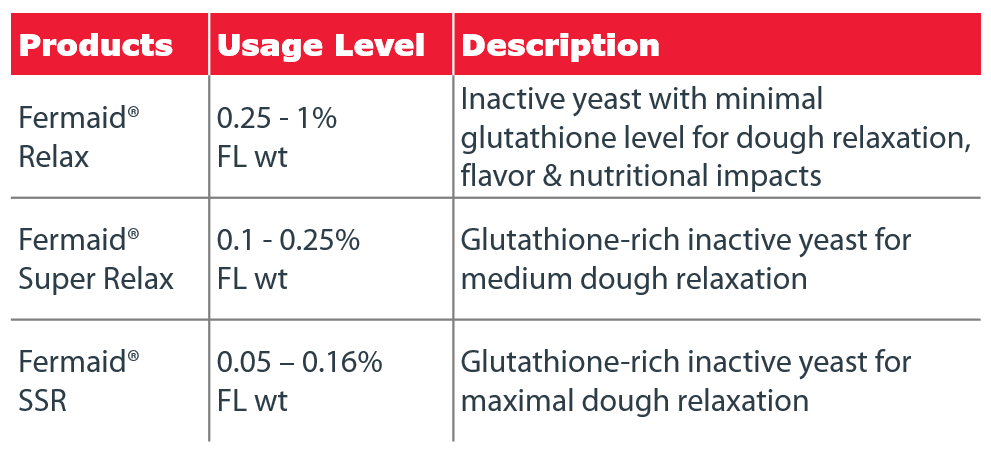

Lallemand Baking offers a yeast-based reducing agent that serves as a natural, clean-label alternative to L-cysteine and bisulfates. Our Fermaid® products, naturally rich in glutathione, facilitate the reduction of disulfide bonds in gluten proteins during dough hydration, enhancing dough softness, stretchability, and pan flow.

The Fermaid® GSH range acts as a dough relaxer, substituting the less desirable L-cysteine. This improves dough handling and extensibility, minimizes tearing, shrinkage, and snap-back during processing, and reduces mixing time.

Fermaid® GSH yeast products can be used in a wide range of bakery applications, including pizza dough, tortilla, baguettes, bread, buns and rolls, pastry dough, laminated dough, bagels, pretzels, Melba toast, rusks, etc.

- Improves dough extensibility and machinability.

- Reduce tearing, shrinkage, snap back, and ovalization of the dough and minimize break & shred lines.

- Energy savings: reduce mix time by 20%.

- Replace chemical-reducing agents such as L-cysteine hydrochloride and sulfites.

- Speed up gluten network development, increase output, and save on energy & water-cooling capacity. Accelerate processing of the pie dough, eliminating the need for dough retarding.